Perhaps you’ve come up with a great new invention idea. Ideally, you’d like to develop this idea into a real serially-manufactured product that will be put on store shelves around the world, and your company will make a lot of money selling it. The bad thing is that the “make a lot of money selling it” part won’t just happen overnight. It will take a lot of time, dedication, hard work, and sleepless nights to develop, manufacture, and sell your new idea. If you are ready to go down that road, this is the perfect article for you. We are going to discuss the importance of the prototypes and the necessary steps that you need to take to come up with the perfect prototype for your new product design.

Coming up with a prototype for your product is all about learning, as each time you come up with a prototype version of your product design, you will learn something new that will help you along the way. They are built at various stages within the process so that industrial engineers and designers can test and assess their design solutions in a real-world context. In most cases, a prototype is a three-dimensional portrayal of a product idea. It could be a simple hand fabricated model or a highly refined version produced by a professional prototype manufacturing company. A prototype can help you test your solution with potential users of the product to evaluate performance, function, and usability. Since the final version of the prototype is a replica of the product you tend to manufacture, it will also help you get feedback from stakeholders and investors before investing in your idea.

All this being said, the process is exhausting and time-consuming, so you should be aware of the various stages of the process that shouldn’t be overlooked. To make things easier for you, we’ve compiled this short guide with simple steps to get the idea of how prototype manufacturing works.

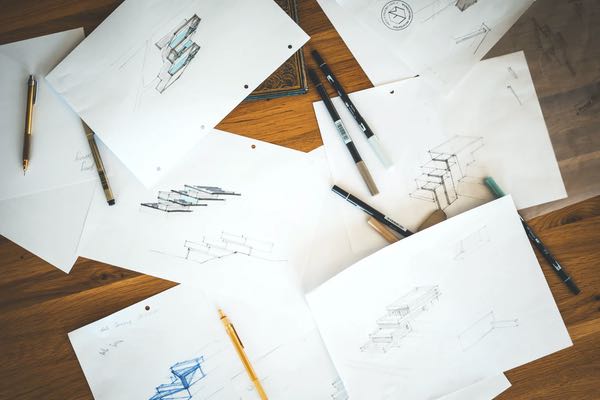

Come Up With A Concept Sketch For The Product Design

First things first, come up with a concept sketch and put your product design on paper. By drawing your idea on paper, you will be able to visualize your prototype in greater detail. While you are still in the early stages of creating your prototype, you’ll probably have a million ideas running through your head competing with each other. Do yourself a favor and put everything on paper as you never know which idea will prevail in the and. Plus, having a concept sketch can also come handy if you ever need to defend your intellectual property ownership down the path.

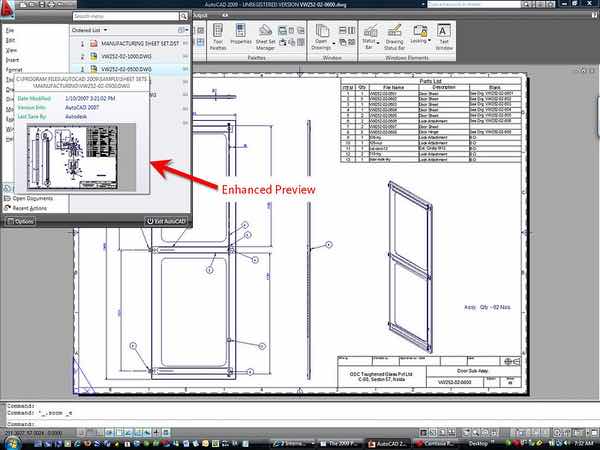

Create A Virtual Product In AutoCAD

The next step is to create a digital sketch of your idea in AutoCAD. The design tool is widely used by design engineers and other professionals to create 2D and 3D renderings of new product designs. The 3D render will let you rotate and animate your virtual sketch, thus visualize the sketch from all angles. Afterward, you can further transform your 3D render into a photorealistic prototype and have an idea of how a physical version of your new product design will look. With the help of the virtual prototype, you will finally have a clear view of the product’s size and dimensions. Coming up with this early mockup will also enhance the reputation of your product from the very beginning, as it will show that you are serious about the product’s design and willing to go the extra mile to create the perfect one.

Create A Physical Prototype

Once your new product is rendered appropriately, it’s time to start developing your prototype’s physical representation. Even though there are numerous ways for developing physical prototypes, 3D Printing and CNC prototyping remain the two most used and most reliable possibilities on the market.

3D printing has revolutionized the prototyping industry since you can mass-produce prototype samples quickly by joining simple inputs using a rapid prototyping method. It’s massively used for prototype development in industries that require frequent and disposable prototypes for visual representation purposes such as jewelry, accessories, and other consumer goods. Besides, it’s remarkably cost-efficient and offers limitless visual customization options. Still, the printed prototypes can only be used for visual representation, lack functionality, and are fragile with moderate surface finishing.

On the other hand, CNC machining can design the near-perfect and functional replica of your product and is widely used to showcase a working demo of the product to potential clients. CNC prototyping is perfect for industrial equipment, medical devices, and many more. The physical prototypes made using CNC machinery are highly functional units and, in most cases, can be used as a final product. They are of much higher quality than 3D printed versions. On the negative side, CNC machines are expensive, and the machines’ operation requires expert assistance. Consider developing a fully functional CNC prototype using the services of a third-party professional prototype manufacturing company.

Refine The Prototype To Perfection

As this is the stage when the prototype goes through a series of redesigns to meet the desired expectations, this stage of the process is the most time-consuming of all. This is where you try to set right some structural or functional problems of the prototype or decide to expand or decrease the functionality of the product. When working on your prototype refinement process, always keep yourself updated with current trends in product design to appeal to your target audience and maximize profitability.

Also, be prepared for changes as nearly every product must undergo some changes before it hits the market. Keep in mind that the product manufacturing industry is continuously evolving, and so should your product. Never stop updating the prototype and keep experimenting with new ways on how to improve your final product before you put it in mass production. Patent your product close to a year before making official product disclosure to prevent plagiarism and duplication of your innovative new design.

Final Words

These simple and crucial steps are the four cornerstones of every product prototyping. Once you have a finished prototype of what the real-world product should look and function like, you are technically ready to apply for a patent and locate a reliable manufacturer that can produce your product at a competitive price.